Definitions and Equations

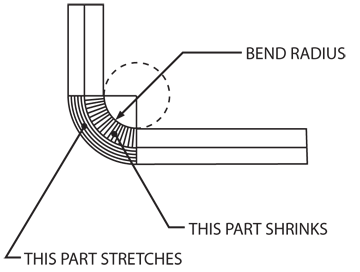

The Bend Radius is the portion of the metal that is curved. The part of the metal on the outside of the bend stretches, while the metal on the inside shrinks. Through the center is a line which does neither.

The dimension of this line becomes the Bend Allowance.

Often, this dimension is calculated simply as

Thickness (T) divided by 2. However, here we are using the more accurate equation:

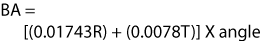

where BA is Bend Allowance, R is the Radius of the bend, and T is the thickness of the metal.

The dimension of this line becomes the Bend Allowance.

Often, this dimension is calculated simply as

Thickness (T) divided by 2. However, here we are using the more accurate equation:

where BA is Bend Allowance, R is the Radius of the bend, and T is the thickness of the metal.

A WORD ON DIMENSIONS

Any measure of length may be used: inches, millimeters, miles, however you must be consistent. Mixing length dimensions will give you inaccurate answers.

However, the bend allowance equation is written using degrees. Any other angular measurement, such as radians, will not work correctly.

Any measure of length may be used: inches, millimeters, miles, however you must be consistent. Mixing length dimensions will give you inaccurate answers.

However, the bend allowance equation is written using degrees. Any other angular measurement, such as radians, will not work correctly.

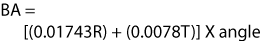

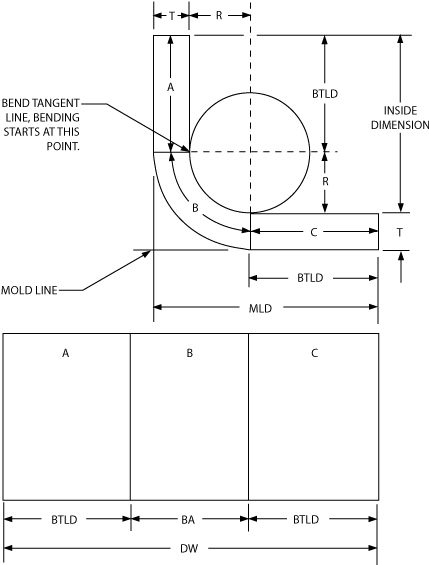

This illustration defines the vocabulary commonly used in flat pattern layouts. MLD is the Mold Line Dimension, or the length of a flat. This dimension is defined by the blueprint. The BTLD, Bend Tangent Line Dimension, is the length of the MLD that is not involved in the bend. It is derived by subtracting the Setback from the MLD.

As can be seen with the drawing, the Setback for a 90 degree angle is T (thickness) plus R (radius). BA is the Bend Allowance, the length of the material in the bend. DW, developed width, is found by adding everything up.

As can be seen with the drawing, the Setback for a 90 degree angle is T (thickness) plus R (radius). BA is the Bend Allowance, the length of the material in the bend. DW, developed width, is found by adding everything up.

Click here to return to the main page.